CCS

Technology

CCS is a technology that captures CO2 and permanently stores it deep in the ground. The technology, which is proven and has existed for decades, captures CO2 emissions that come from a plant or industrial site and stops them from being released into the atmosphere.

Separation

Carbon Storage

Hub Concept

Key Concept Assumptions

- Regulatory forecast based on floating wind roadmap

- Located outside existing license areas

- No onshore facilities, ie. receiving hub

- Similar to Stella Maris concept in North Sea

- CNLOPB regulates any development

- No additional seismic needed

CO2 storage assessments indicate

TOP 10 STORAGE AREAS IN OFFSHORE NEWFOUNDLAND

can hold approximately

60 years

of Canada’s entire 2022 emissions (43GT).

Newfoundland

and Labrador’s

total emissions are just

0.18%

of Canada’s total emissions, with oil and gas production representing 1.26MT of GHG

Eastern

Canada

61M

However, provinces with direct access to eastern waterways represent potential annual emissions of 61MT, establishing the potential for NL to be a

storage hub

for carbon with storage potential in the gigatonne range.

Northeast

USA

187.1 M

When considering emitters along the US Northeast, NL becomes a potential

regional hub

for carbon storage.

with advances in technology and the development of port infrastructure,

transportation

to offshore NL and coordinated injection could supersede other planned approaches to GHG mitigation in the region.

NL offshore has all the geologic requirements needed for safe CO2 storage as demonstrated by a long history of storing hydrocarbon gas within the reservoirs.

A future technical storage assessment by OilCo will add much‐needed quantification to the perceived CO2 storage opportunity in Newfoundland and Labrador’s offshore.

Project

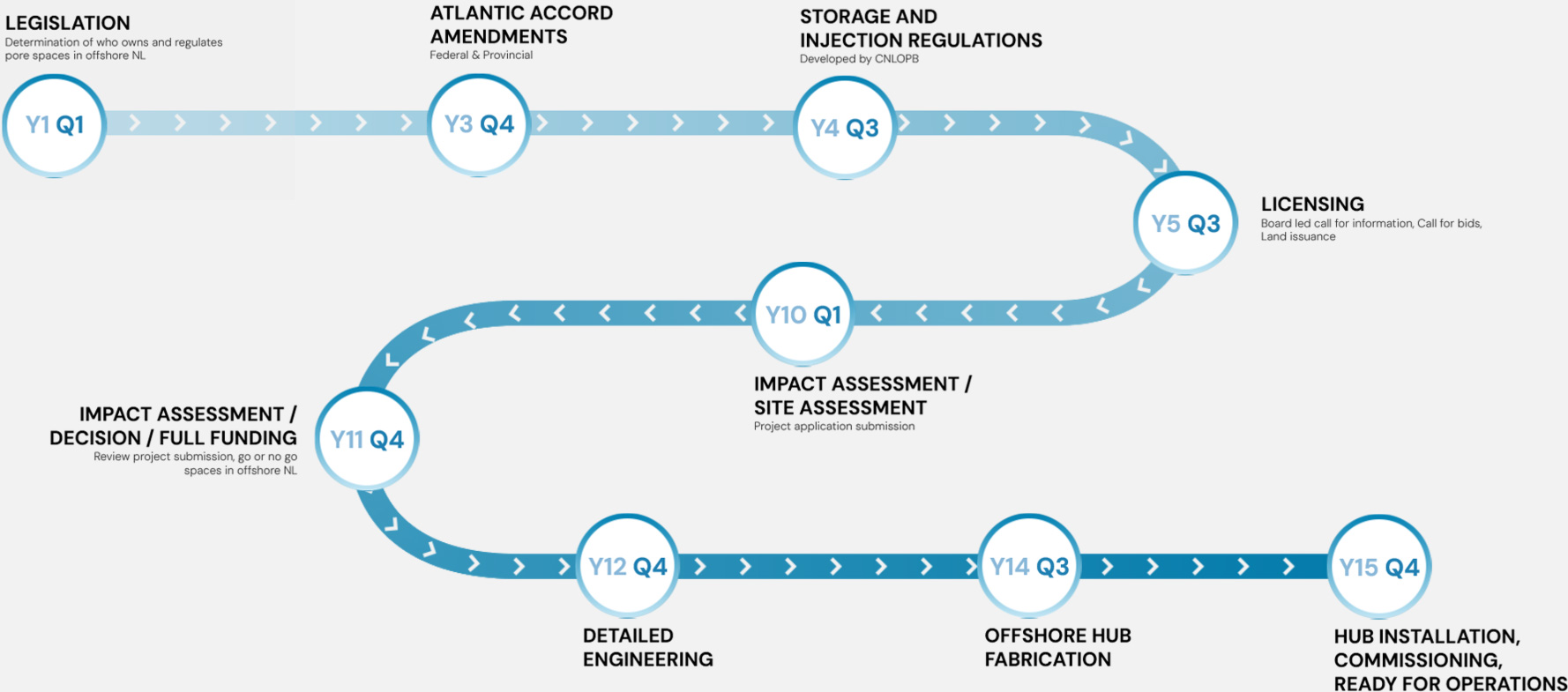

Roadmap

CCUS has the potential to significantly reduce emissions in the NL offshore in the near to medium term should technical advances continue at their current pace. This will require concerted research and development effort as CCUS has never been applied in an offshore context before.

Timeline

Offshore Atlantic Canada has extensive expertise in offshore project execution, from engineering to fabrication to installation.

The CCS roadmap projects significantly more time is likely to be spent on regulatory and legislative development than project execution.

15 Years

Legislation

Determination of who owns and regulates pore spaces in offshore NL

Establishing who owns and regulates the pore spaces for CO2 storage is foundational for CCS development. Pore spaces refer to subsurface geological formations that can securely store CO2. Offshore Newfoundland and Labrador (NL) falls under federal and provincial joint jurisdiction as governed by the Canada-Newfoundland and Labrador Atlantic Accord Implementation Act.

- Current Status: Ownership of these subsurface resources is not explicitly defined, leading to potential regulatory and legal uncertainties.

- Next Steps: Clarify ownership and control mechanisms to define responsibilities for site access, storage rights, and liability management. This involves legal interpretations of the Atlantic Accord and may require legislative amendments or new regulations to ensure compliance with federal and provincial laws and international CCS standards.

Atlantic Accord Amendments

Federal & Provincial

The Atlantic Accord, originally focused on oil and gas activities, was amended in 2018 to regulate air emissions in offshore areas. These amendments provide a legal basis for CCS projects but do not yet fully address the specific requirements for CO2 injection and long-term storage.

- Importance for CCS: Without explicit provisions for CCS, project proponents face regulatory uncertainty. Detailed amendments must specify CO2 storage as an allowable activity, clarify the regulatory framework for such operations, and harmonize federal and provincial responsibilities.

- Action Plan: Propose further amendments to the Accord to integrate CCS-specific provisions. These should outline criteria for site licensing, environmental impact assessments, and operator liability. Cooperation between federal and provincial governments will be crucial to finalize these amendments, ensuring they align with international best practices and policies under agreements like the Paris Accord.

Storage and Injection Regulations

Developed by CNLOPB

The Canada-Newfoundland and Labrador Offshore Petroleum Board (CNLOPB) is the regulatory body for offshore oil and gas activities, and it needs an expanded mandate to regulate CCS storage and injection. This expansion would cover CO2 injection into geological formations and long-term storage to ensure environmental safety and compliance.

- Components of Regulation:

• Site Characterization: Regulations should include comprehensive geological surveys to identify suitable storage formations.

• Injection and Monitoring Standards: Develop operational standards for CO2 injection, plume tracking, and pressure management to mitigate risks.• Risk Management and Emergency Protocols: Include requirements for risk assessments, contingency planning, and emergency response mechanisms in case of CO2 leakage or other incidents.

• Environmental Compliance: Establish stringent monitoring, measurement, and verification (MMV) requirements to ensure that CO2 remains securely stored.

- Implementation: CNLOPB can collaborate with industry experts and global CCS leaders to draft these regulations. Piloting regulatory processes on smaller-scale projects will help refine the framework before widespread adoption.

Licensing

Board led call for information, Call for bids, Land issuance

A structured licensing process is needed to facilitate private sector participation and investment in CCS. This would mirror existing oil and gas licensing systems, involving a call for information, bid submissions, and land issuance for potential CO2 storage sites.

- Steps in Licensing:

• Call for Expressions of Interest: CNLOPB invites stakeholders to provide data on potential CCS opportunities and areas of interest.

• Site Evaluations: Conduct geological and environmental assessments to identify suitable storage areas with high CO2 containment potential and low environmental risk.• Bid Solicitation: Open competitive bidding for licenses to explore, develop, and operate CCS sites.

• Land Issuance: Award licenses for CCS operations, with conditions tied to performance, environmental compliance, and ongoing monitoring.

- Long-Term Benefits: This approach ensures a transparent, competitive process that attracts industry expertise and capital. Additionally, it aligns with CNLOPB’s mandate to manage resources responsibly and optimize economic and environmental outcomes.

Impact Assessment / Site Assessment

Project application submission

Before CCS projects can proceed, they must undergo a formal regulatory review to assess environmental, technical, and geological suitability.

- Process:

• Environmental & Geological Assessments: Evaluate site integrity, CO₂ containment security, and potential risks to marine ecosystems and groundwater.

• Public & Indigenous Consultation: Gather stakeholder input to address concerns and incorporate local knowledge.• Regulatory Submission: Project proponents submit applications detailing site assessments, risk management, and compliance measures.

Projects meeting initial criteria advance to the decision stage for formal approval or rejection.

Impact Assessment / Decision / Full Funding

Review project submission, go or no-go spaces in offshore NL

Following regulatory review, authorities determine whether CCS projects can proceed based on environmental and technical feasibility.

- Process:

• Regulatory Review: Agencies evaluate compliance, potential risks, and mitigation strategies.• Stakeholder Considerations: Indigenous, community, and industry feedback inform final decisions.

• Final Determination: Sites are either approved, conditionally approved (requiring additional safeguards), or deemed unsuitable for storage.

Approved projects move to detailed engineering and permitting, while no-go areas are ruled out for future development.

Detailed Engineering

After project approval, detailed engineering focuses on finalizing the design, technical specifications, and construction plans for the CCS facility.

- Process:

• Site-Specific Engineering: Develops injection well designs, CO₂ transport infrastructure, and storage monitoring systems.• Process Optimization: Finalizes capture technologies, compression systems, and CO₂ handling methods to maximize efficiency.

• Risk & Safety Analysis: Conducts hazard assessments and integrates emergency response plans.

• Cost & Procurement Planning: Defines materials, equipment, and construction schedules to align with regulatory and budgetary constraints.

Engineering plans are completed, enabling procurement, fabrication, and site preparation for CCS deployment.

Offshore Hub Fabrication

With engineering designs finalized, this phase focuses on constructing the offshore CCS hub, including CO₂ injection platforms, pipelines, and supporting infrastructure.

- Process:

• Modular Fabrication: Key components such as injection wells, compression units, and pipeline systems are prefabricated in onshore facilities for efficient offshore assembly.

• Integration & Testing: Equipment is tested for operational reliability, ensuring compliance with safety and environmental standards.• Offshore Installation: Deployment of subsea infrastructure and surface platforms, followed by connection to capture and storage systems.

• Regulatory & Safety Compliance: Adherence to offshore construction protocols and government approvals before commissioning.

A fully assembled offshore CCS hub, ready for commissioning, testing, and operational handover.

Hub Installation, Commissioning, Ready for Operations

Following fabrication, the offshore CCS hub undergoes installation, system integration, and final testing to ensure operational readiness.

- Process:

• Installation & Assembly: Offshore transport and placement of injection wells, pipelines, and processing units, followed by system integration.

• Commissioning & Testing: System validation, including pressure testing, leak detection, and control system calibration to ensure safe CO₂ injection and storage.• Regulatory Approvals: Final inspections by authorities to confirm compliance with environmental, safety, and operational standards.

• Operational Readiness: Training for personnel, emergency response drills, and final verification before full-scale CO₂ injection begins.

The CCS hub is fully operational, marking the transition from development to active CO₂ capture, transportation, and storage.

Asset-Specific

Retrofit CCS Concept

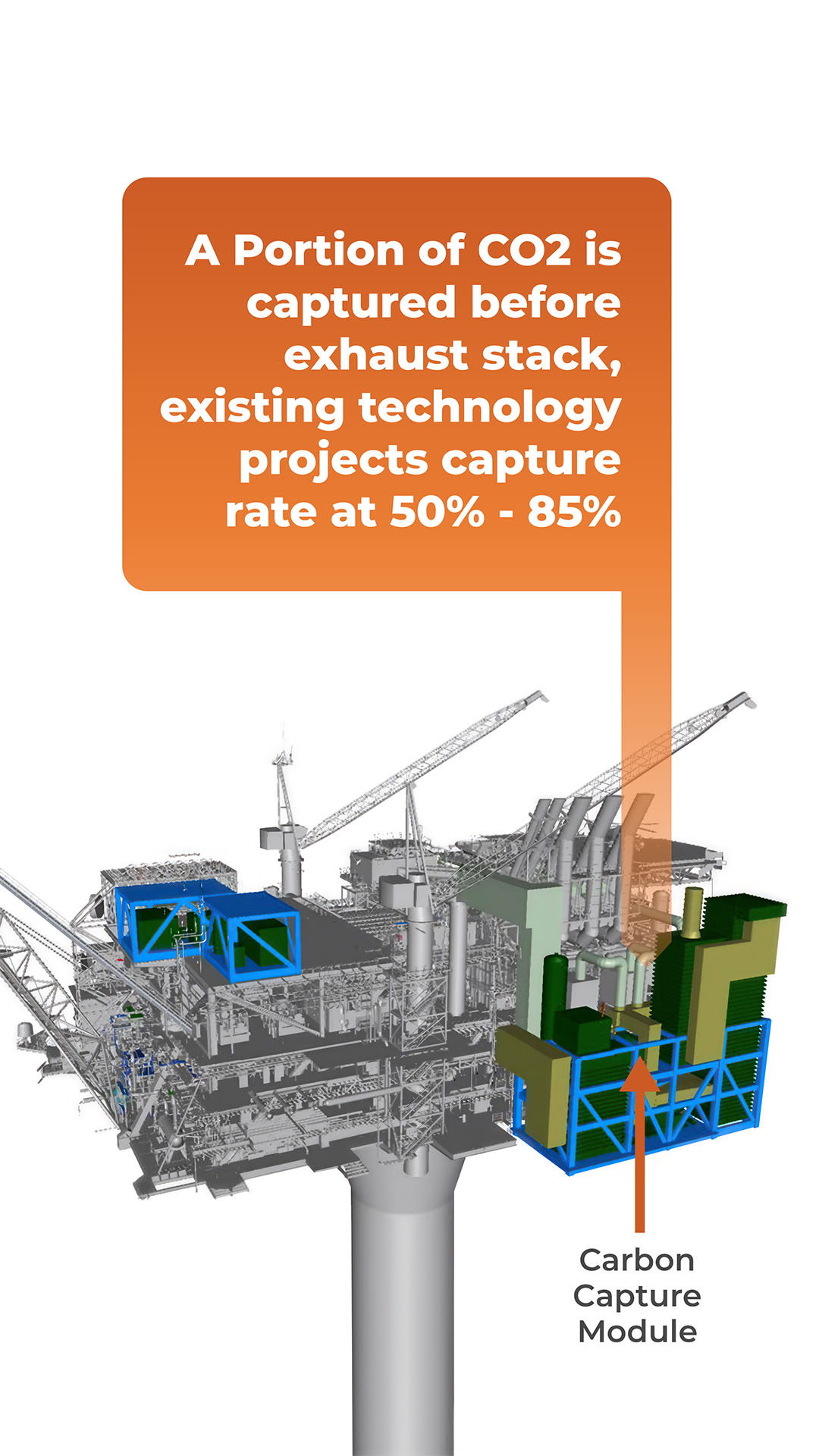

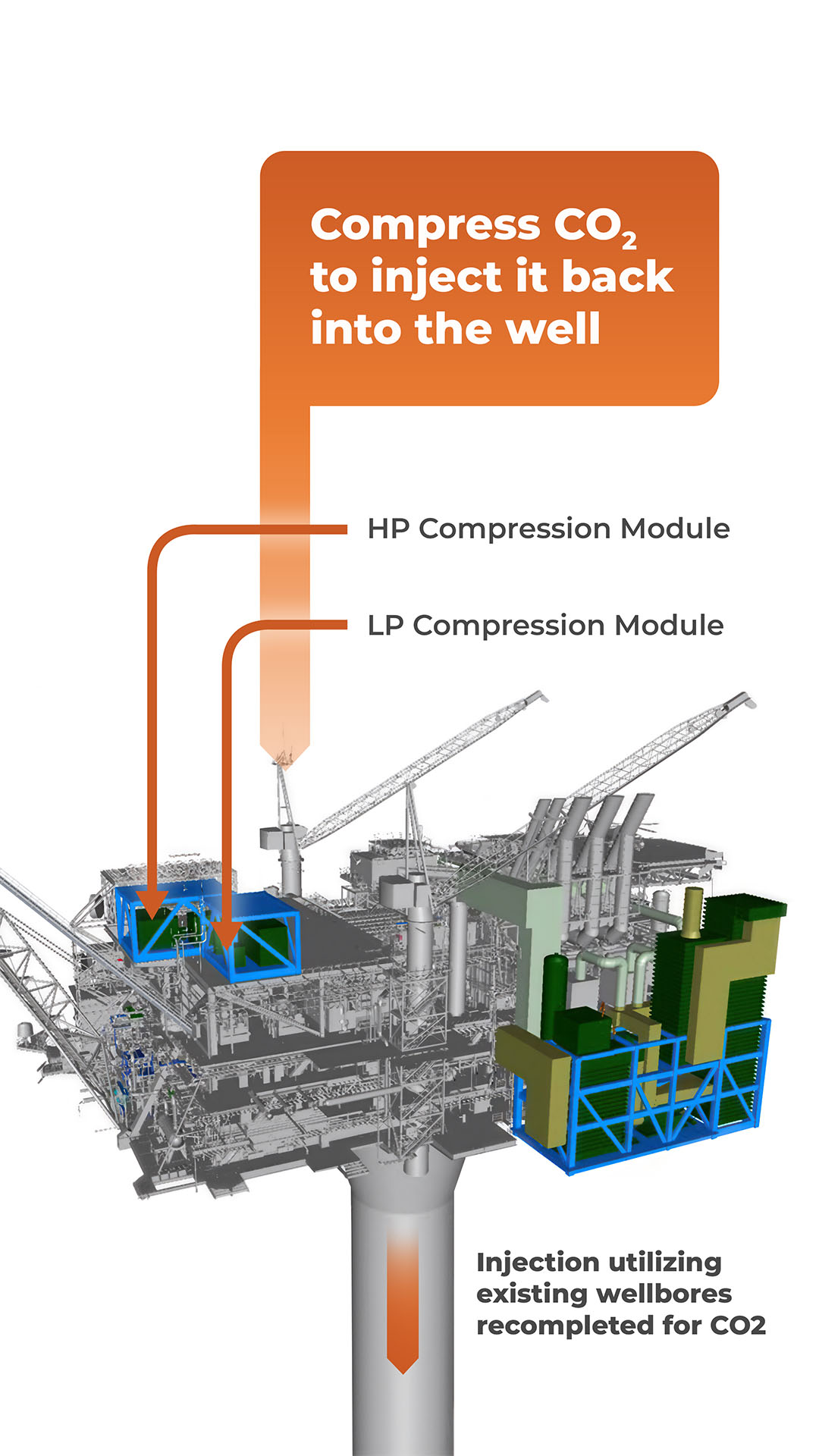

Utilize post-combustion carbon capture technology

(i.e. chemical absorption using amines)

Assume installation using a “CCS module” similar to ACC Just Catch Offshore

Installed on an existing brownfield asset

CO2 storage in existing reservoir utilizing existing slot / wellbore

- Abandon existing well as required

- Drill to a new target and recomplete

NL Offshore Installation Implications

Even though post‐combustion carbon capture may be considered the most feasible capture technology option for offshore NL, it has many challenges for offshore implementation. While it may be one of the relatively lower cost technologies to capture emissions from turbine exhaust, it still remains a high‐cost endeavor on

an absolute basis.

Environmental

Carbon Capture technology is that it introduces potentially new chemicals into the offshore environment that are used for CO2 absorption. These new chemicals may complicate the offshore processes.

Safety

CO2 is an inert gas and will not present a fire risk to a platform. However, CO2 is toxic at high concentration and will also cause asphyxiation if oxygen concentrations are too low.

Regulatory

The project would almost certainly result in a development plan amendment involving the regulator and statutory certification. Downtime and deferred production would need to be considered in the economics of the project.

Space and Weight Constraints

A critical balance would need to be found between the target carbon capture efficiency, available space, weight considerations, and electrical power demands.

Energy Requirements

A critical balance would need to be found between the target carbon capture efficiency, available space, weight considerations, and electrical power demands.

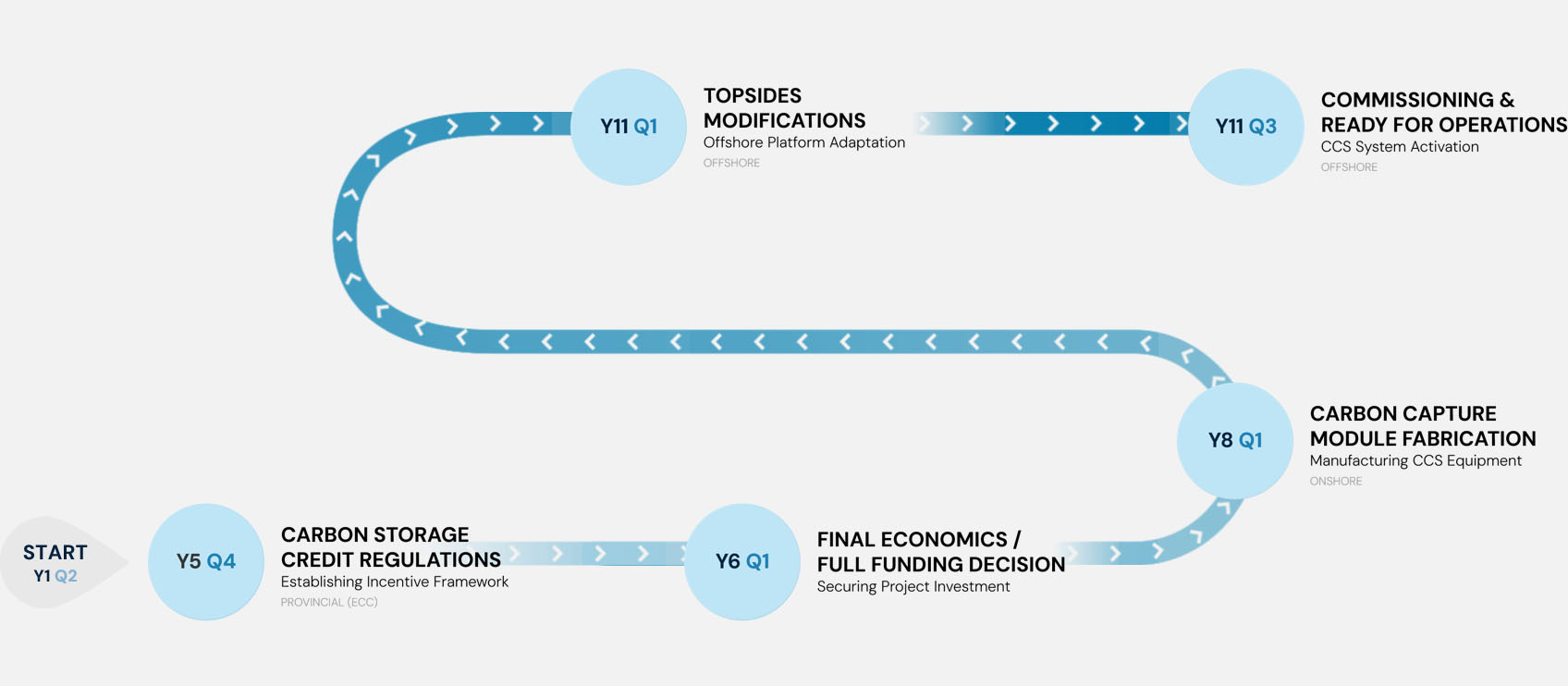

Project Roadmap

-

~ 10 yr Project

-

~ 5 years for Legislation / Regulations

-

~ +5 years for Project Execution

-

Post Combustion CCS modules have not been installed offshore anywhere else in the world (first time application)

Carbon Storage Credit Regulations

Establishing Incentive Framework

Carbon credit regulations provide financial incentives for CCS adoption, ensuring economic viability. These policies define eligibility, credit issuance, and compliance requirements for offshore carbon storage.

Process:

- Regulatory Development: Provincial and federal agencies establish credit issuance frameworks.

- Industry Consultation: Engagement with stakeholders to align regulations with investment needs.

- Market Integration: Linking carbon credits to trading systems to enhance project returns.

Outcome: A structured credit system that supports CCS investment and aligns with emissions reduction targets

Final Economics / Full Funding Decision

Securing Project Investment

A final investment decision (FID) ensures that financial, technical, and regulatory risks are addressed before committing capital.

Process:

- Economic Modeling: Evaluating project costs, revenue potential, and return on investment.

- Funding Secured: Government incentives, private sector commitments, and stakeholder agreements finalized.

- Risk Assessment: Review of long-term cost drivers, credit market stability, and regulatory compliance.

Outcome: A structured credit system that supports CCS investment and aligns with emissions reduction targets.

Carbon Capture Module Fabrication

Manufacturing CCS Equipment

Fabrication of post-combustion carbon capture modules is critical for offshore deployment. These systems remove CO₂ from turbine exhaust before emissions are released.

Process:

- Engineering & Procurement: Selection of technology, materials, and fabrication partners.

- Manufacturing & Testing: Assembly of compact, offshore-compatible CCS units with performance validation.

- Logistics Planning: Coordination for module transportation to offshore facilities.

Outcome: Fully built and tested CCS modules, ready for installation on offshore platforms.

Topsides Modifications

Offshore Platform Adaptation

Modifying offshore platform topsides to accommodate carbon capture modules and integrate them with existing power generation and exhaust systems.

Process:

- Structural Reinforcement: Ensuring platform stability and weight-bearing capacity.

-

System Integration: Connecting CCS units to turbine exhaust and CO₂ transport infrastructure.

-

Safety & Compliance: Meeting offshore regulatory and operational standards.

Outcome: Platforms are retrofitted and ready for CCS operations without disrupting oil production.

Commissioning & Ready for Operations

CCS System Activation

The final phase involves testing, regulatory approval, and the start of carbon capture operations.

Process:

-

Performance Testing: Verifying CO₂ capture efficiency and system functionality.

-

Regulatory Approvals: Final inspections and compliance checks.

-

Operational Training: Preparing offshore personnel for CCS system management.

Outcome: The offshore CCS system becomes fully operational, capturing emissions and reducing the carbon footprint of oil production.